How do I choose a label material?

The choice of label material is a critical decision for businesses, impacting everything from product branding to durability. This choice becomes even more complex when considering the vast array of materials available and their suitability for different applications. In this guide, we delve into how to choose the right label material, with a special focus on finding and working with the right suppliers, including those for private labels and thermal labels.

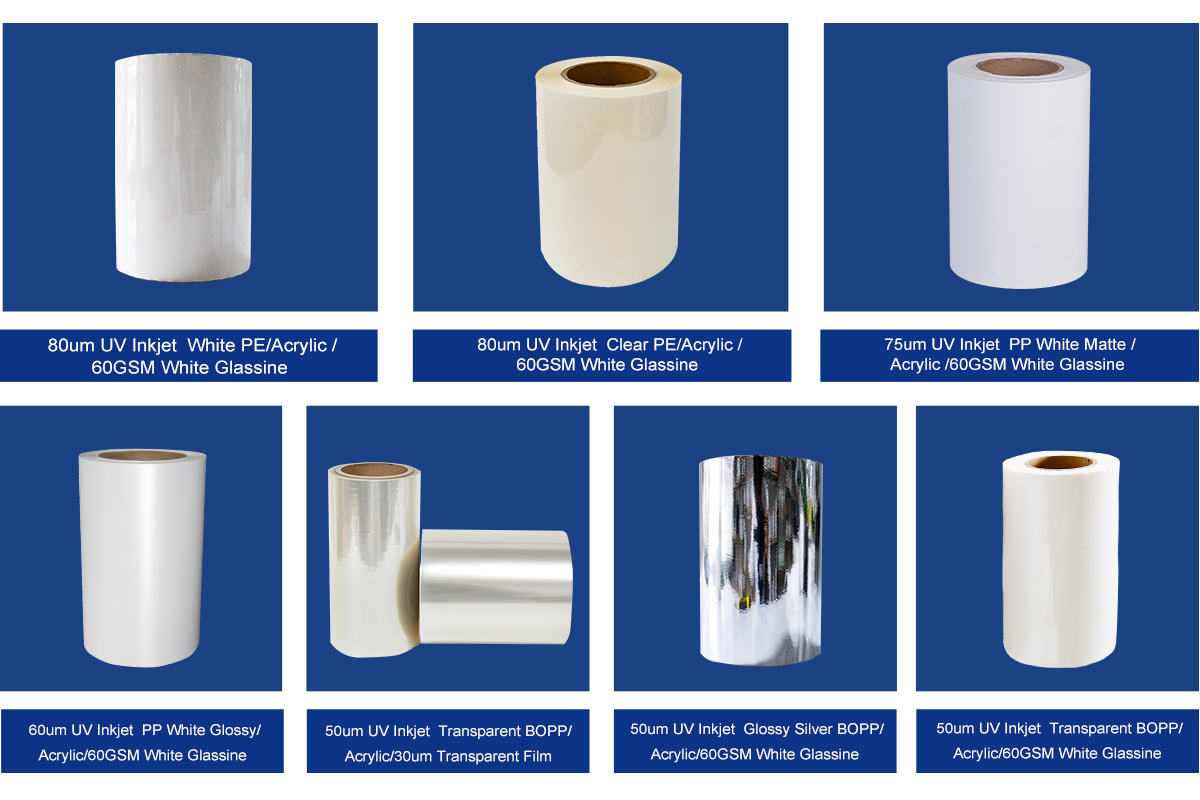

Understanding Different Label Materials: Label materials vary widely, each with unique properties and applications. Common materials include:

Paper Labels: Economical and versatile, suitable for indoor use. They're perfect for temporary applications but are less durable against moisture and wear. Polyester and Polypropylene Labels: Known for their durability, these materials are resistant to water, oil, and chemicals, making them ideal for products exposed to harsh conditions. Vinyl Labels: Extremely durable and weather-resistant, vinyl is perfect for outdoor applications. Each material serves different industries and purposes. For instance, paper labels are commonly used in retail, while polyester finds its use in industries requiring durability.

The Role of Label Material Suppliers: A reliable label material supplier is a key asset for any business. Suppliers not only provide materials but also offer valuable insights into the latest trends and technologies in the label industry. They can assist in choosing the right material based on the product's needs and environmental exposure. For businesses looking for specific solutions, such as eco-friendly materials or high-durability labels, a knowledgeable supplier is indispensable.

Choosing a Supplier for Private Label Raw Materials: For businesses looking to establish a private label, choosing a supplier becomes even more crucial. A good private label raw material supplier should offer: Customization: Ability to tailor materials to unique brand requirements. Quality Assurance: Consistent quality that aligns with your brand's image. Supply Chain Reliability: Efficient and timely delivery of materials. Selecting Raw Material Suppliers for Thermal Labels: When it comes to thermal labels, the material's compatibility with thermal printing technology is paramount. Key considerations include:

Heat Sensitivity: The material should react appropriately to the thermal print head for clear, legible printing. Durability: Especially for labels used in shipping or inventory, where wear resistance is crucial. Supplier Expertise: Suppliers should have a deep understanding of thermal label applications and be able to advise on the best material choices. Best Practices in Working with Raw Material Suppliers:

Effective collaboration with suppliers is essential. Best practices include: Clear Communication: Clearly convey your needs and expectations. Understanding Logistics: Be aware of lead times and delivery schedules. Quality Control: Regularly review supplier performance and material quality. The right label material can significantly influence a product's market success. By carefully selecting and working with the right label material suppliers, businesses can ensure their products are labeled effectively, enhancing both functionality and brand presentation.

Post time: Jan-16-2024